With precise and real-time information, your days of lost inventory and inaccurate data are numbered. Literally.

Just last week, I was sitting at lunch with a client. While enjoying our Baja tacos and sipping a couple of brews, we chatted about the challenges of warehouse inventory. He lamented to me that just this last year, they had an undisclosed number of pounds of product that were moved to some dark recess of a warehouse and was promptly forgotten about. When they stumbled upon the lost inventory, they discovered that it had gone bad. They lost the entire batch due to a breakdown in their management system.

I’m sure many of you have relatable nightmares that you could share over a mug or two. We hear it time and time again- lost inventory due to negligence, misplacement, mis-categorization, mistakes and more. It goes without saying that lost inventory is lost profit. Therefore, plant managers and c-suite members are constantly looking for ways to mitigate loss and increase efficiency.

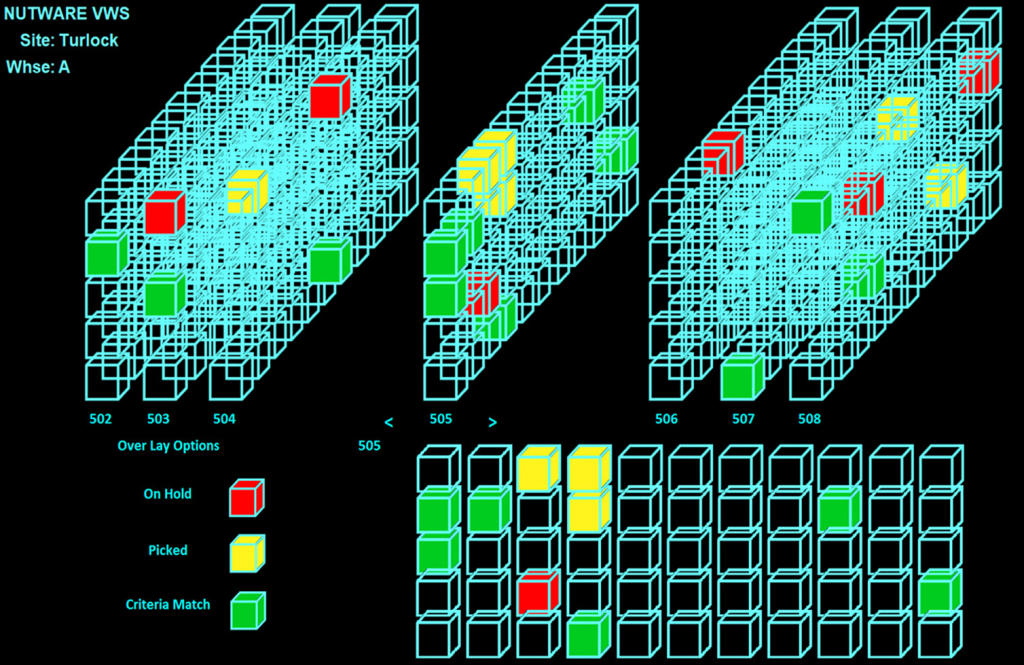

That’s why the Virtual Warehouse System was developed. To make sure that you never lose a bin or profit again. The system relies upon a powerful database software, NutWare, which helps warehouse personnel manage their inventory.

VWS takes management one step further by giving leadership teams as well as warehouse personnel real-time, pin-point accurate data with the added benefit of a 3Dimensional visual representation of the location of any bin with matching criteria. It makes pick lists truly accurate and has the potential to speed the process of picking by massive percentages.

QC Filters drive the data and the interactivity deeper into a robust reporting, management and traceability tool. When combined with the physical attributes of being able to automatically scan bin tags upon approach, 2 bins high and log location upon pull-away, VWS stands to transform your warehouse management system into a highly-effective and efficient operation.