Nutstar would like to introduce “NutStar Market”, a new service exclusive to our client community. This new service allows our members to buy or sell with banner listings. NutStar will approve items such as equipment, machinery, office furniture, devices and perhaps surplus or hash commodity. Our client community includes CFO’s, general management and business owners, which creates a decision-making group that may have interest in buying or selling to other handlers. Our expectation for this Market Place is to provide listings for raw materials of any commodity. Please sign in and view our latest listings.

Category: Featured

From Our Team To Yours…

We would not do what we do if it wasn’t for you, our clients. Though there are challenges in every project, our clients remain our priority. This year, we have added a few fresh faces and shifted some of the team around to new roles.

- Dante Jones and Valerie Miranda are bringing their customer service skills to the team as new Product Support Specialists. They are and continue to be great additions to the team.

- Tigen Bowman is steering the ship, keeping your development moving by managing the product support and programming teams as our On-Site Manager. She is bringing much needed structure to the organization.

- Though Rhiannon McCullough is not a new face, her role has changed significantly. She has been as asset as an excellent product support specialist and we are excited to communicate that Rhiannon has helped shape and is now filling the role of Quality Assurance Analyst, making final checks to all development before it goes out to our clients.

Every staff member we have added is to better attend to your needs in your day-to-day operations. It is a thrill for us to be growing in order to serve you better.

Transform your warehouse into an efficient operation

Bringing The Future To Warehousing With Real Automation

We hear about it all of the time- Amazon and their automated warehouse robots buzzing in pre-determined synchronicity, storing items and retrieving them to be shipped to eager customers in seconds. It can sound other-worldly and high-tech enough to be movie-script worthy. Yet, it’s not that far-fetched, even in the tree nut industry.

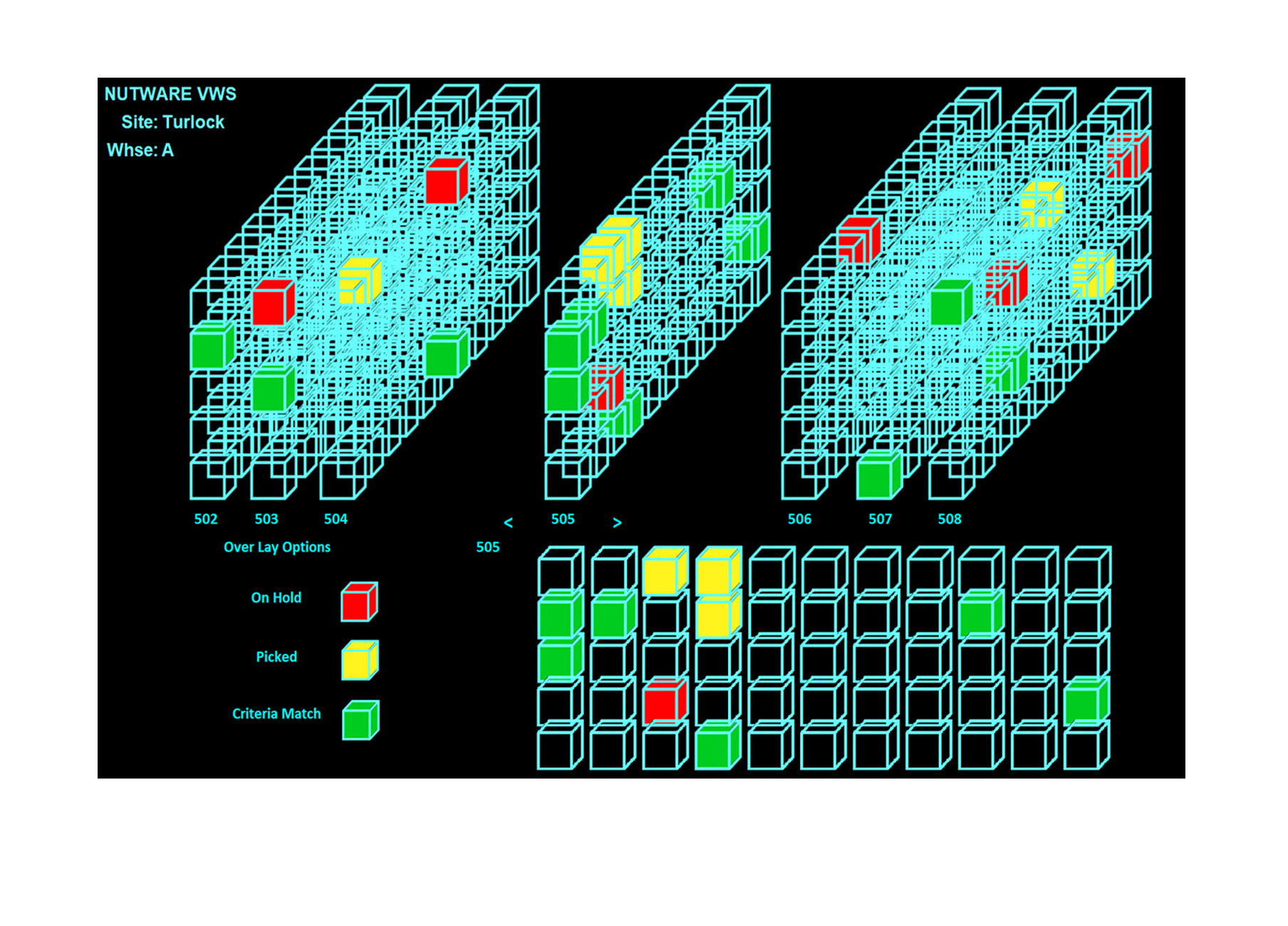

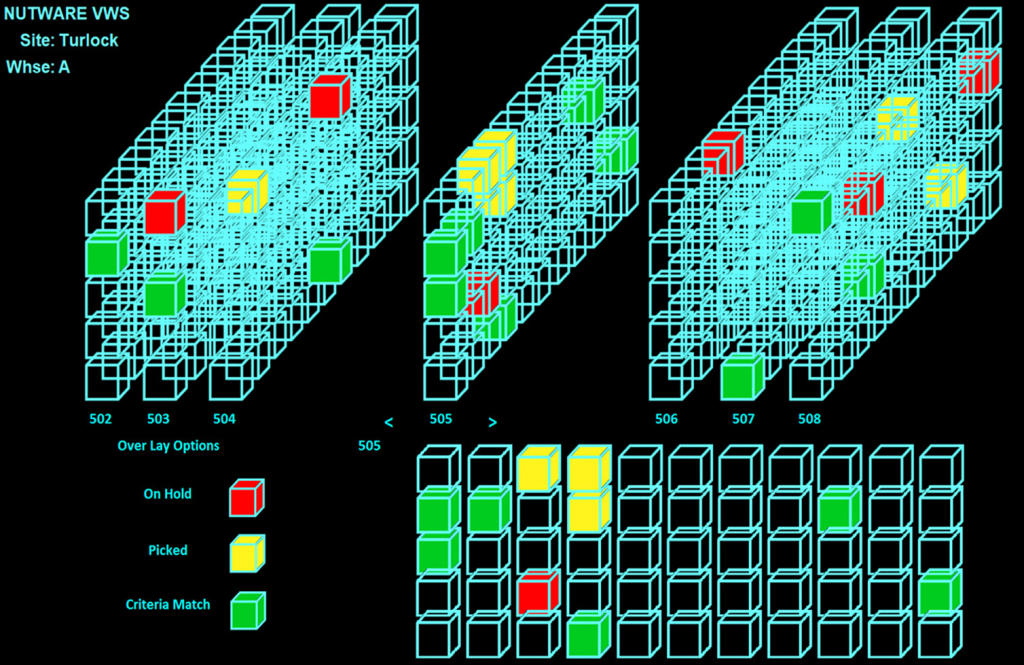

Warehouse system automation uses software, machine learning, robotics and data analytics to automate tasks and procedures. For example, a developed pick list is generated with all of the bins needed to fulfill an order and users pick the first bins that match the pick list criteria, with exact locations, so warehouse workers perform at a much higher efficiency and warehouses themselves become higher-capacity with the possibility of greater scalability and improved performance.

And this is nothing new. This technology has existed for decades in many other iterations. Although, the tree nut industry poses some daunting challenges, like double-stacked loads and volume density issues. NutStar Software has spent nearly 3 years developing a system that works specifically for inventory management within the nut processing warehouse.

Some key innovations have been the development of a system that takes into account the fact that bins full of 5% water content plus the mass of kernels, meats and shells pose a barrier to consistent electronic signals. Our system allows the user to place a bin in any row, position and loft and autonomously track and position its content for future recall in a pick list or fulfill a job list query. This innovation eliminates the need for warehouse workers to manually log locations and contents. It also provides the user with the comfort of never leaving the seat of the forklift upon pickup or drop-off.

One of the most exciting innovations is the 2D and 3D pick list search as well as the QC filter functions. Both allow the user to search for specific categories or identify the exact location of a bin or a set of bins or super-sacks within desired parameters.

When coupled with the powerful grower purchasing, inventory management and sales tracking software, NutWare, the Virtual Warehouse System really comes alive and can be used to it’s full potential. Desktop users will be able to supply pick lists to their drivers with on-board touchpads, with displayed locations for the job. once the load is picked up and transferred to the desired location, the system automatically updates across the entire database, allowing for real-time updates and flawless traceability.

We will continue to innovate and bring you products, systems and solutions to help your operations become more efficient and profitable.

No More Re-Tagging Bins

It was another busy day in the warehouse and the plant manager stood with his hands on his hips. He watched the forklifts buzzing past, heard the trucks pulling up to the scales and he momentarily marveled at the precision and efficiency of the operation.

What was so amazing as he watched a newly-arrived truck being unloaded, was the fact that it used to be so different. Annoyingly, frustratingly different in fact. When a 20-bin load came in from a huller/sheller, one of the biggest headaches he and his team had to deal with was taking an accounting of the new inventory with bin tags that were unreadable. It would slow the entire operation down until new tags were created, printed and slapped on the bins.

Simply put- one of the best decisions of the past few years was to implement a software system that changed the face of the operation’s effectiveness and efficiency.

Here at NutStar Software, we have heard variations of this scenario time and time again. In this particular example, we developed a solution for all tags with standard barcode 39’s and QR codes to be readable and up-loadable into NutWare, regardless of their point of origin. It’s one way we are helping your inventories balance out.

It continues to be our pleasure to offer confidence in your processes by providing custom solutions for your team and your business. Today, we offer agile development processes that allow for rapid identification of your need, custom development, and implementation. We thrive on helping you to make your goals a reality.

Thanks for letting us help you feed the world.

Merced Mayor Visit

Since our move from the Turlock office to our new location on the corner of 18th and V St. in downtown Merced, we have had the opportunity to host several city officials. This last week members of the NutStar team welcomed Merced City Mayor Matt Serrato. We spoke with Mayor Serrato about new business opportunities in the City of Merced as well as ways that we might positively contribute in the coming months and years.

We look forward to partnering more with the city and its good people!

Pictured left to right- (Dante Jones- Product Specialist, Aaron Pham- Developer, Frank Ramos- Owner, Mayor Matt Serrato, Matt Shumaker- Operations Director, Tigen Bowman- On-site Manager, Cindy Ramos- Finance & Sales, Ana Maldonado- Developer)

NEW Android Scanners 2020

Introducing a new platform for Cipherlab scanners: ANDROID. The RK95 and RS51 Droid scanners provide the same functionality as the Cipherlab 9700 series but with newer features and added benefits. As a bonus, our clients will no longer need to send in scanners for the newest update. These Droid scanners allow for our programmers to send the updates via online.

Please click for more information and scanner specs on links provided below.

For purchasing options, please call the office and ask for our Scanner Sales Representative.